Here at Co-ordSport we understand that paying serious attention to detail, can give the best results – for both performance and reliability. If you want to push that engine or transmission to the limits and for it to have a long life, then build those assemblies right, then maintain them well. OK, it often takes longer to do things right and double check tolerances and correct fit, etc., meaning it may be more expensive, but it’s cheaper than a blown unit and doing the job twice! Not to mention replacing worn and broken parts.

Read below an interesting situation we experienced recently, which surprised many people:

- Block

- Piston

- Rings

In our endeavour to keep learning, we not only sell the parts, but we get involved in people’s builds and do some modifying and building ourselves. Liam, who works in our Buying Dept., has for a long time modified his own Ford cars and lately started helping out some other Ford enthusiasts to rebuild their engines. Some of the experiences have meant steep learning curves, but he’s learning fast and one of the primary lessons is that there aren’t any short cuts to doing a good job, whilst also not skrimping to save a few pennies during any build, which could result in many pounds of expenditure soon after, when problems or failures occur. If not fitted correctly and within recommended tolerances, then mechanical parts can and will wear very rapidly.

One of Liam’s Ford pals brought an ST250 ecoboost engine to him recently, which was suffering from the engine having lost oil pressure or a lack of oil and in turn had spun a Rod bearing on Cylinder 2 , despite a recent professional forged internal rebuild. Although, the owner did admit to not checking the oil level regularly – fail to prepare, prepare to fail?!

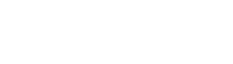

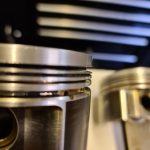

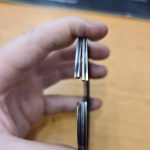

Anyway, what was of particular note and concern with these pistons was the wear on the top ring lands, despite the usual areas of wear of detonation/stress not being evident. We discussed this with various experts, who confirmed what we had was very unusual. The pistons were Manley brand, which we sell regularly and we don’t have issues with the product, so we asked the advice of Manley themselves – Trip Manley himself was great, he directed us straight to the likely cuplrit, badly fitted pistons/poorly gapped rings:

Honestly, I’m quite certain that there weren’t any “defective piston issues” here. Based on the pics, it appears that something was going on in this engine….causing the issues. The skirts are pretty badly worn…..either too tight….or, more likely, from serious piston rock

(was detonation evident?). The cylinder bores look scratched up badly as well. Am wondering if the rings were budding??

Something was definitely going on….the piston ring lands/grooves did not get damaged like that from nothing……

Trip Manley

Manley Performance Products, Inc.

After studying the parts further, we are fairly sure the pistons were not fitted to a block that had the piston to bore tolerances accurately set, and the rings probably weren’t gapped, at all! We understand that this well know tuner carries out these conversions in situ, without removing the engine block from the car and we have to question the wisdom of that – sometimes it may be OK, and with cheaper forged pistons, using softer alloys, they may expand/adapt/wear easierer, but on this occasion, they failed, possibly not helped by the owners lack of care and maintenance. Let’s hope he’s learned his lessons!

Nobody will ever know if the stress caused by the poorly fitted pistons and rings, jerking their way up and down the bores, caused the stress that caused the bearing to wear, or it was simply a lack of oil, but paying attention to the fitment details when building powerful engines is absolutely essential.

More details about Ring gapping and fitment is available in our Blog HERE and HERE, plus you can buy the necessary tools from Co-ordSport and Part-Box online.

- Block

- Piston

- Rings

That was just the initial appraisal, because to avoid the same problem, we have to know what may have happened.

Now the serious job of re-assembling the engine with new parts begins, whilst ensuring the manufacturer’s recommended tolerances are adhered to – so first job, measure the bores and make sure they’re not oval! Then Liam can decide which sized pistons he needs to order. Luckily, his employer, Co-ordSport, tries to keep a big range of sizes and brands, for quick delivery!