Instructions for Fitting Evo 3 Constant Gear

- Strip center differential housing (#1) completely and mount in lathe

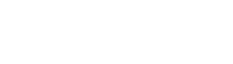

SHEET 1

- Machine old constant gear (#2) off diff housing by using a face grooving tool to groove out the existing weld (#3). The groove should be 3mm wide x 7 to 9mm deep (#4).

- ATTENTION !! When machining this weld out, use caution. Cut to 7mm and then check if you have cleared the weld. If not go deeper, but try to cut only until you have cleared the weld,- minimum as possible. The reason for this is that there is a ground finished surface (#5) behind the weld to locate your new gear.

- Mount the differential housing in a press and remove old gear.

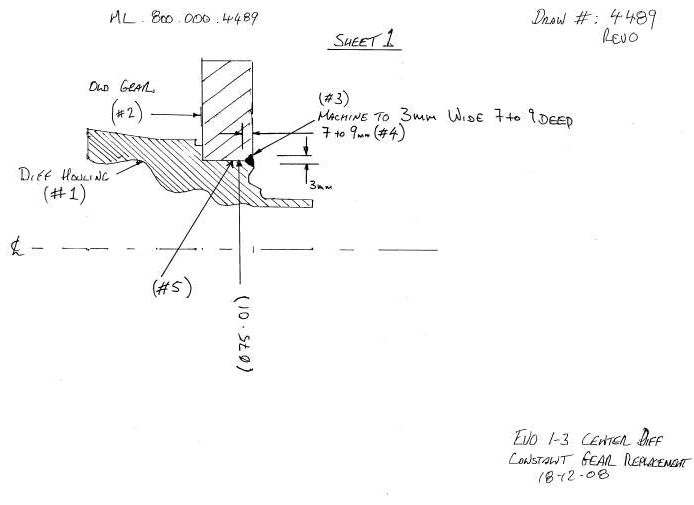

SHEET 2

- Press on new gear (#6) with the 3mm (LARGER) Bore chamfer (#7) to the outside.

- ATTENTION !! Coat Gear teeth and areas not to be welded with heat sink protection paste such as “Anti Heat” manufactured by TEMPIL U.S.A or similar.

- Weld new gear to shaft (#8) using Pulse MIG. THIS MUST BE DONE BY A QUALIFIED WELDING TECHNICIAN.

- Remount differential housing in lathe and machine weld straight.

- ATTENTION !! If using a center differential with a dog change gear train, it may be necessary to machine the differential housing and end cap in area (#9), depending on what ratio is used.

Click the Images to Enlarge