Co-ordSport Group Is Proud To Be A Supplier To Donkervoort, A Leading Design & Technology Company

Donkervoort Enters Production Of Non-automotive Products

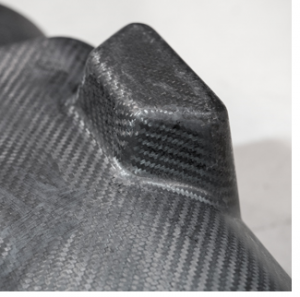

Donkervoort Automobielen B.V. has for the first time in its history started producing carbon-fiber parts for non-automotive products. This business expansion must however be seen next to an even larger development. Within the European Union sponsored SME2 project Donkervoort is now challenged to – in the next two years – develop a mass production method (at a competitive price) of the award-winning Donkervoort patented EX-CORE® carbon-fiber material.

Promising

Donkervoort sees this SME2 challenge as a promising business opportunity. Firstly – because EX-CORE® creates immensely strong and incredibly lightweight carbon components – aimed at creating a contribution to weight reduction in the mass-production of electric cars, where batteries are responsible for a significant weight-increase. And apart from that, if Donkervoort is able to develop the mass production method for EX-CORE®, opportunities might also arise in other industries.

Donkervoort entering the development of EX-CORE® mass production is the direct result of its 2018 win of the European Innovation Grant in High-Tech Materials and Advanced Manufacturing Technologies. Honoring the fully in-house developed EX-CORE® single-shot carbon-fiber production method, combining multiple layers of carbon-fiber with a specially invented foam core.

Lightweight

For Donkervoort Automobielen B.V. 2018 has been a year to remember anyway. It has been celebrating its 40th company birthday and launched its latest and most innovative car to date: the Donkervoort GTO-40. Of course, in the well-received GTO-40, EX-CORE® carbon-fiber technology was widely used for the first time. With weight reduction and increased strength as a result. Adding an important step to the automotive industry that – if the SME2 project can be successful – might also open the way to a significant weight reduction in mass produced electric cars.